Dimensional Metrology Inspection Services

Dimensional Inspection at AIS

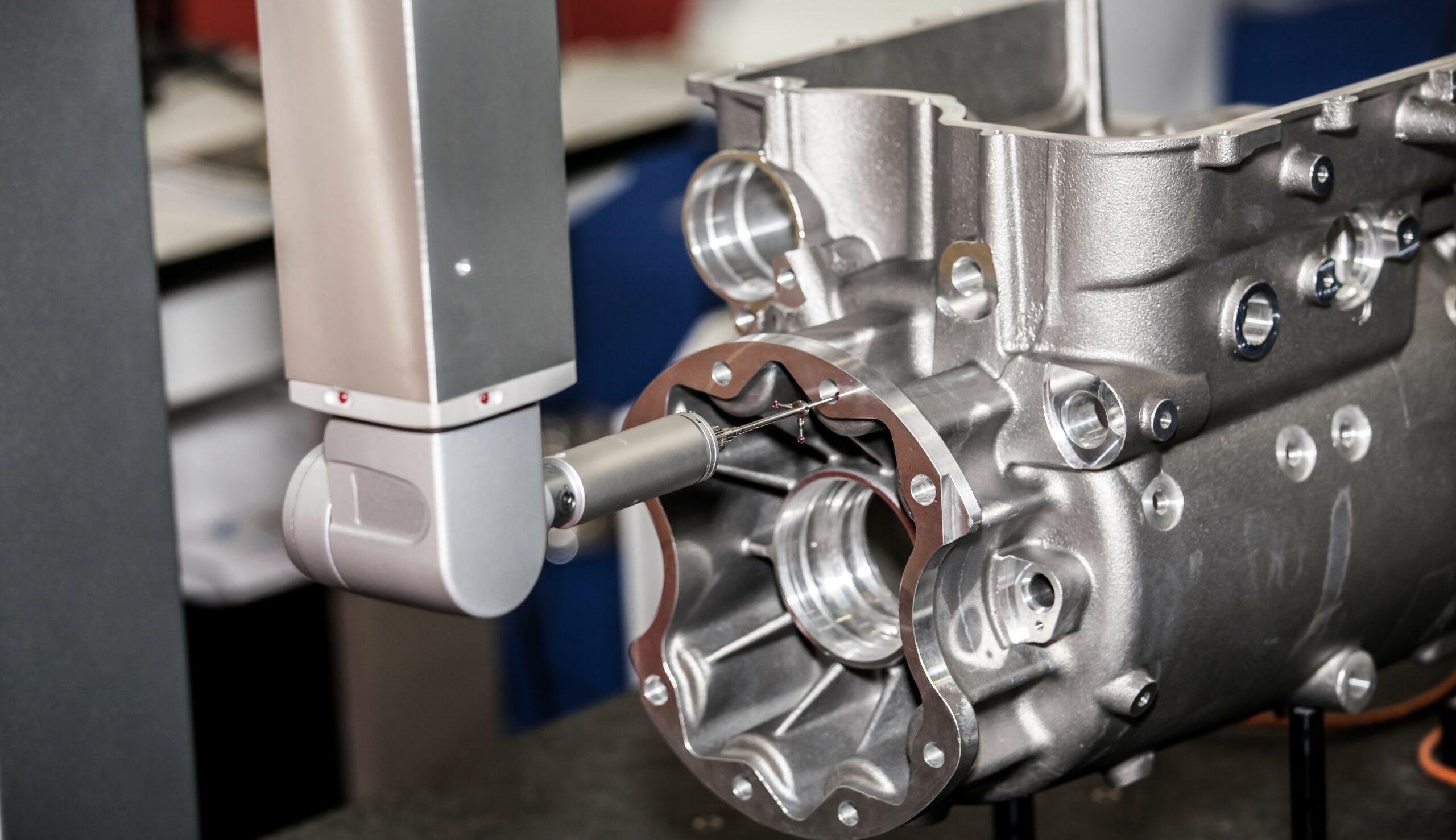

Dimensional inspection and analysis is the core service AIS was built on and remains at the heart of everything we do. Every day, our metrology lab operates in a temperature and humidity-controlled environment, where we measure and assess part characteristics with ultra-high precision. Our team inspects everything from historic WW2 airplane engine blocks to modern medical implants, backed by some of the most advanced equipment available. This includes our Leitz Infinity PMMC Coordinate Measuring Machine (CMM) housed in our ultra-high accuracy lab, which boasts an impressive uncertainty of just 0.000012”. With over 60 accredited dimensional inspection parameters and 24 years of experience, AIS has the expertise and capabilities to handle any inspection challenge.

Dimensional Measurement Applications

At AIS, we use the parameters set by your unique project to determine which dimensional inspection equipment is the best fit for the application. Whether simple directional measurements or complex GD&T analysis, we have the tools to perform:

- Linear Analysis: We perform the basics of dimensional measurement such as diameters, depths, and lengths to ensure part accuracy.

- Reverse Engineering: We offer various CAD Models from basic .stl to Parametric models with a full feature tree. By creating CAD models to aid in part design, part manufacturing, and efficiency or supporting final inspection, we support an efficient manufacturing process.

- Assembly Verification: After component inspections are complete, the sub-assembly may need to be verified against the specifications to ensure proper part performance

- Tooling and Fixture Inspection: Tooling and fixtures must be inspected to ensure they meet design requirements to achieve accurate results

- Surface Finish: Surface finish must be inspected to ensure parts are aesthetically acceptable and functional for the application.

- Form Analysis: Form is a notable contributor to overall measurement accuracy. Flatness, roundness, and cylindricity are some of the most common applications crucial to maintaining measurement precision

- Geometric Dimensioning & Tolerancing: GD&T is critical to ensure a part meets the design intent. It allows users to achieve tighter tolerances and meet industry standards while enabling part interchangeability between manufacturers

Dimensional Inspection Tools & Technologies

Traditional hand tools like calipers and micrometers have long been used in manufacturing facilities and quality labs for a variety of applications. However, for parts with complex geometries or tighter tolerances, we employ advanced tools such as CMMs, 3D laser scanners, and industrial Computed Tomography (CT) systems.

Suited for a variety of applications, most metrology tools are equipped to perform dimensional analysis:

- Calipers, Micrometers, and Height Gages

- CMMs and Vision Systems

- Optical Comparators and Surface Plates

- Thread Gages and Go/No-go Gages

- 3D Laser Scanners and Industrial CT Systems

- Laser Interferometers

- Profilometer and Surface Finish analysis tools

Within these methods are variations in the accuracy and reliability of the technology. A caliper is a perfectly adequate tool to measure the length of a screw with a .005” tolerance, but a heart stent with a .0002” tolerance would require more accurate equipment. As part tolerance and accuracy narrow, so do the suitable inspection equipment options.

Your Dimensional Analysis Results

Choosing the appropriate equipment to perform dimensional analysis depends on the size, shape, features, and required tolerance of a part. The resulting inspection report is a traceable document that can be used to make program and equipment adjustments or as validation to keep production moving.

You can be confident that the data provided can be used to guide decisions in design, production planning, and validations while driving other important decisions in your processes.

Our Capabilities

AIS is an accredited inspection service provider with over 100 separate inspection parameters on our certification. We continue to add new technology to our lab and expand our accredited capabilities every year. Our metrology lab is held to 68℉ and our measurement uncertainties are consistently the best in the industry.

For projects large and small, we have the tools to perform dimensional inspection on a wide range of parts. The types of dimensional metrology equipment you’ll find in our lab include:

- OGP Vision and Multisensor Systems

- Hexagon Coordinate Measuring Machines

- RX Solutions Computed Tomography Systems

- Sensofar Optical Profilometers

- Mitutoyo Surface & Form Equipment

- InspecVision 2D Sheet Metal Inspection Systems

- 3D Laser Scanners

We continue to expand our metrology and engineering inspection capabilities to meet the growing demands of our customers and the industries we serve. In addition to providing inspection services in our lab, we also provide onsite programming and training support. Our inspectors will come to your facility and teach your team how to write and run programs. We can even bring our portable arm, laser tracker, or laser interferometer and perform inspections onsite.

Our inspectors are all GD&T trained and several of our staff are ASME GDTP Certified. We understand that dimensional inspection is crucial to ensure part safety and reliability in every industry; from implantable medical devices to aerospace engines.

Dimensional inspection is the foundation we built our organization on. It was the first area in which we achieved accreditation and we are proud to continue to deliver dimensional metrology services to customers nationwide.

Get in touch to explore how we can help you meet your part inspection needs.