Measurement Uncertainty: What It Is and Why It Matters

In the world of precision measurement, measurement uncertainty is a critical concept that often goes unnoticed, even though it plays a large role in ensuring accuracy and quality in manufacturing and quality control processes.

Setting the Stage: The Cold, Hard Truth About Measurements

Imagine you’re in a quality control lab measuring the diameter of a small aluminum part. You take a measurement with your digital caliper and record the value. You toss the part in your pocket for safekeeping, then later decide to double-check your work with a different tool. The result is a slightly different number. So, which one is right?

Here’s the catch: It’s impossible to be completely certain.

No matter how sophisticated the tools or methods, measurement uncertainty always exists; every measurement carries some level of doubt.

What Is Measurement Uncertainty?

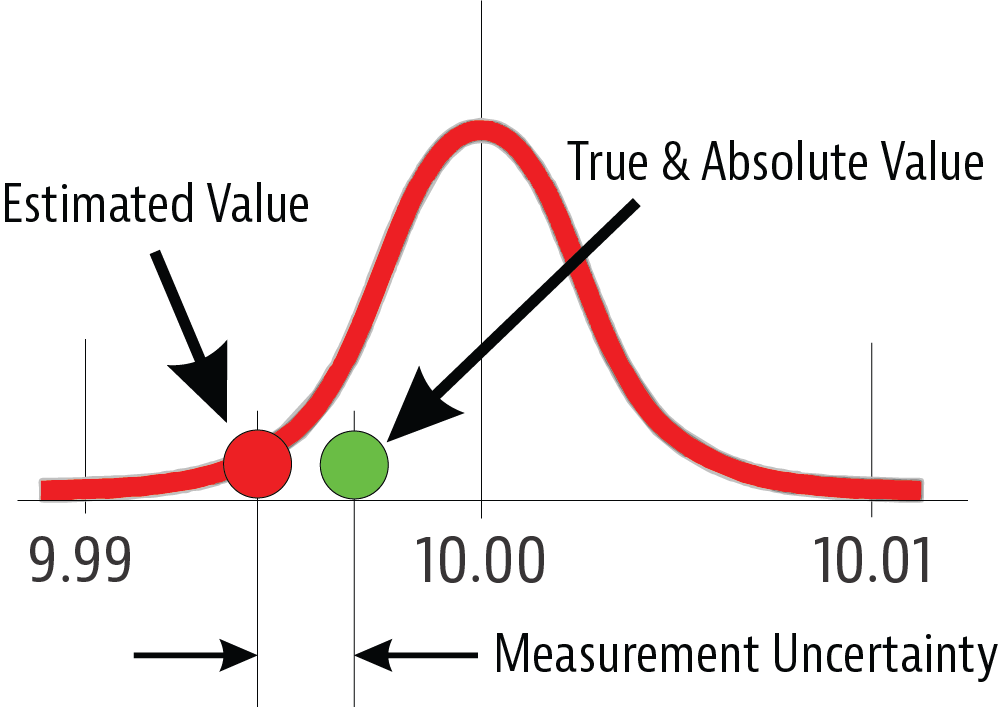

Measurement uncertainty is the difference between the true value of a measured part (which we can never know for sure) and the value your instrument gives you. While we strive to get as close as possible to the true value, we can never achieve absolute certainty.

Even the best tools—whether it’s a digital caliper, micrometer, or a Leitz Infinity CMM—will have some margin of error. This is where measurement uncertainty comes in: it helps define how much "wiggle room" there is around the measured value. Whether you’re calibrating equipment or inspecting a workpiece, measurement uncertainty is a silent element always factored in.

Why Measurement Uncertainty Matters

For every measurand—that is, the specific quantity you’re measuring—there exists a true, exact value. When measuring something like the diameter of a part, the goal is to determine that value as precisely as possible. The problem is that no measurement method is perfect, and there’s always some degree of inaccuracy.

Here’s why this matters:

- Compliance and Quality Control: Manufacturing industries often require parts to be within certain tolerances. Understanding measurement uncertainty helps you determine if a part truly meets those standards.

- Confidence in Results: Knowing your level of uncertainty allows you to confidently report measurements and assess their reliability.

- Risk Management: By accounting for uncertainty, you can reduce the risk of producing out-of-tolerance parts, which can lead to costly recalls or failures.

On our inspection reports, the uncertainty of a measurement result is expressed "Uncertainty (µin)" and represents an expanded uncertainty expressed at approximately the 95% confidence level using a coverage factor of k=2. We follow the National Institute of Standards and Technology (NIST) guidelines for measurement uncertainty.

How to Measure Uncertainty

The most common method for estimating measurement uncertainty is a gage repeatability and reproducibility study, often shortened to GR&R. In a GR&R study, multiple operators measure multiple parts multiple times, and the results are compared to estimate the variability in the measurement process.

While this gives us insight into repeatability (how consistent measurements are), it doesn’t necessarily ensure accuracy (how close the measurements are to the true value). High repeatability can still lead to inaccurate results if the tool is consistently wrong in the same way.

In other words, great repeatability might just mean you’re repeatedly wrong.

Shrinking the Uncertainty

So how do we reduce measurement uncertainty? There are two main strategies:

- Improving Accuracy and Precision: We want both accurate and repeatable measurements. Precision refers to how close repeated measurements are to each other, while accuracy refers to how close those measurements are to the true value. Shrinking the uncertainty means narrowing both.

- Using Better Tools and Following Standards: Modern measurement technologies are constantly evolving to provide greater precision. Instruments that can measure smaller units with greater reliability naturally help reduce uncertainty. But it’s not just about having the right tools—following standards is just as important.

Standards like those from the American Society of Mechanical Engineers (ASME) help guide us in managing and reducing uncertainty. For instance, the B89.7 series covers everything from measurement planning to building uncertainty statements and estimating risk. By adhering to these guidelines, we can create more reliable and consistent measurements.

What Causes Measurement Uncertainty?

Measurement uncertainty is not a standard figure across all applications. It’s influenced by a variety of factors, including:

- The environment you’re measuring in (e.g., temperature, humidity)

- The reference element used for calibration

- The measurement equipment and how it’s set up

- The software and calculations involved

- The operator’s skill and experience

- The material being measured

- The procedure you’re following

Why You Should Care About Your Uncertainty

Understanding and managing measurement uncertainty is critical for ensuring the quality of your measurements. It gives you the confidence to report results that are as accurate and reliable as possible.

Knowing how far off your measurement might be—and why—lets you take informed actions to improve your processes and outcomes. In other words, by being certain about your uncertainty, you can achieve better accuracy, quality, and overall success in your projects.

So next time you measure that aluminum part, remember that what seems like a small difference can be significant, and knowing your measurement uncertainty helps ensure you’re staying within the right bounds.

If you're interested in brushing up on your own metrology skills, we offer training year round over multiple metrology disciplines. Our Metrology Boot Camp course covers everything from dimensional measurement basics to gage R&R studies and metrology software validation and includes new, hands-on content focused on Measurement Uncertainty.

March 24, 2025