PC-DMIS Gear for Precision Gear Inspection

Precision Gear Inspection

At Advanced Inspection Services (AIS), we’re driven by a commitment to delivering high-precision dimensional inspection solutions—and that means staying at the forefront of technology. Our adoption of Hexagon’s PC-DMIS Gear software reflects this focus, enabling us to deliver accurate, efficient, and comprehensive gear measurement services.

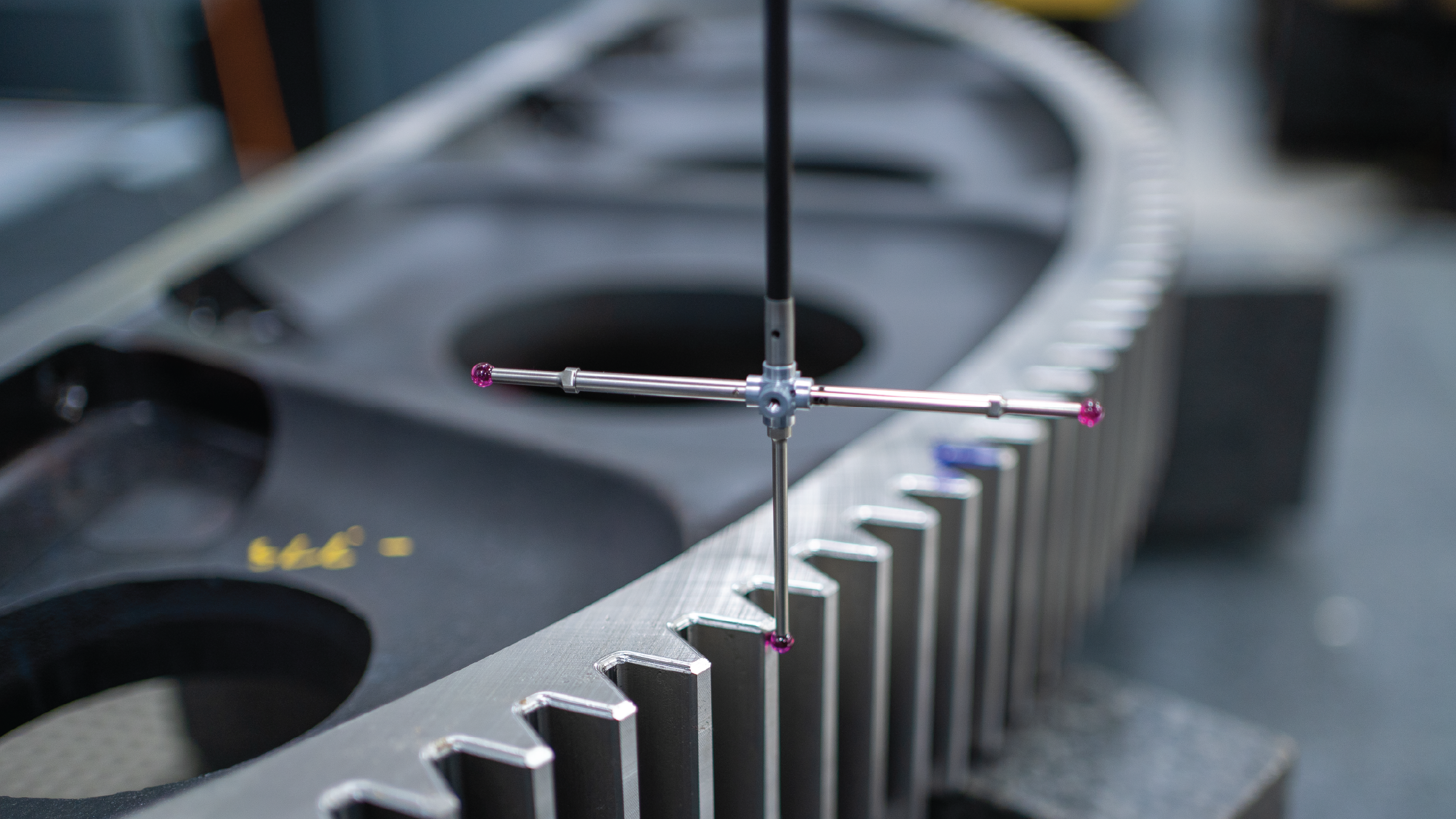

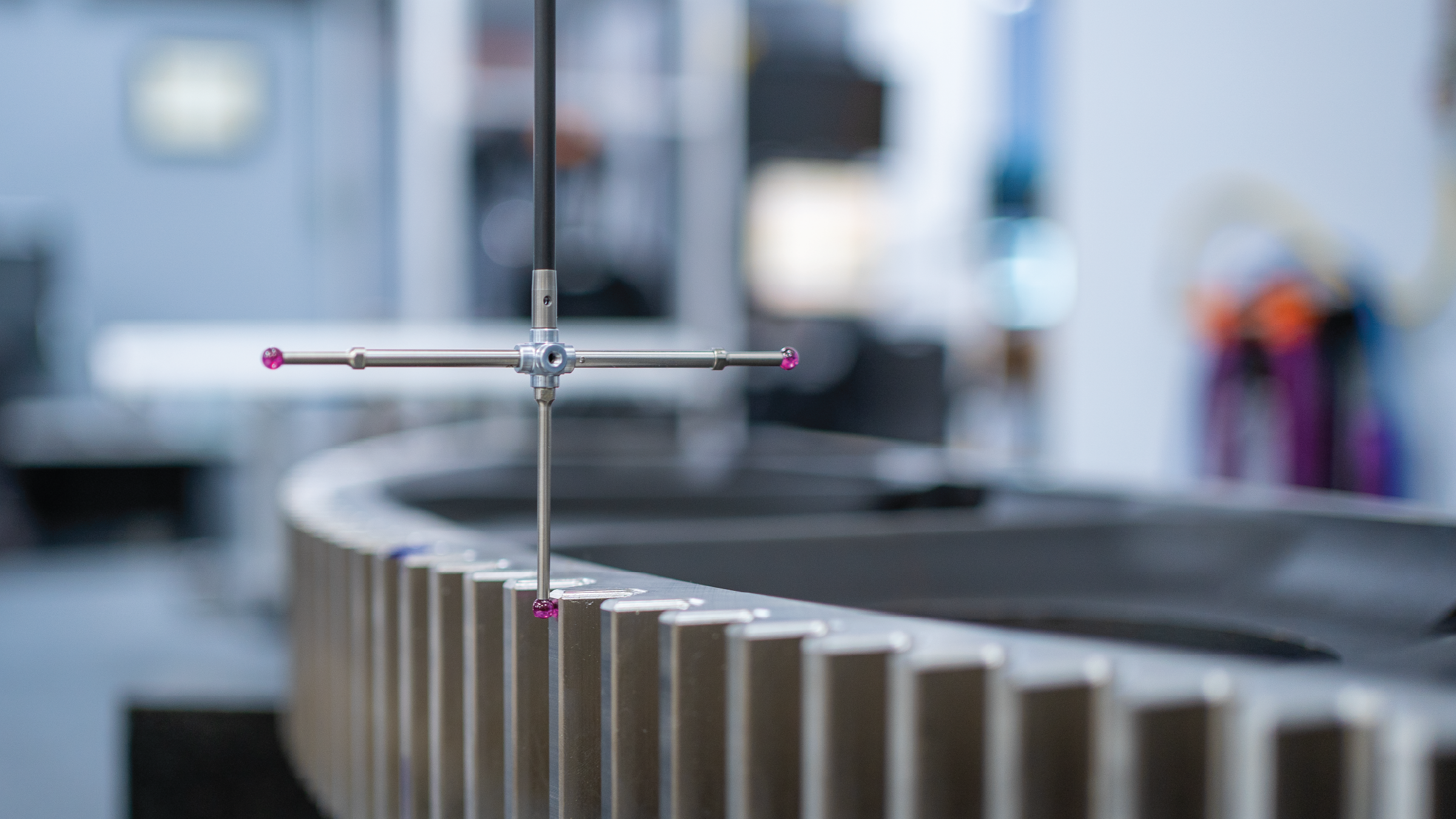

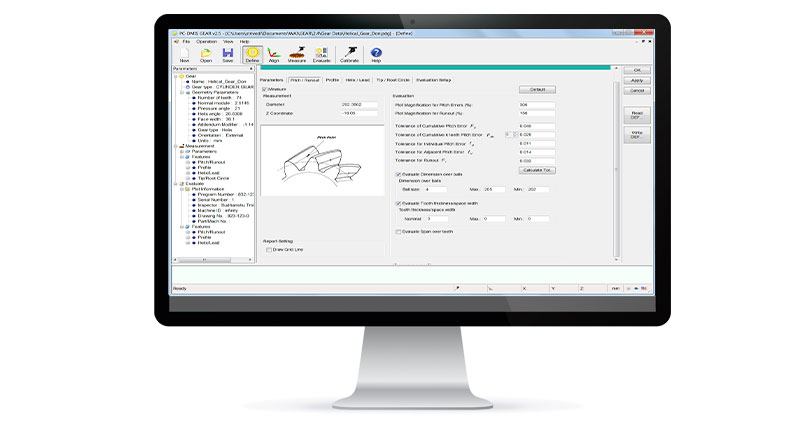

Streamlining Inspections

Gear inspection has traditionally been a complex task, requiring specialized knowledge to properly orient gears and interpret measurement results. PC-DMIS Gear simplifies this process by utilizing a rules-driven form that allows for the straightforward creation of inspection programs and reports. This approach enables our team to set up and execute measurement cycles with increased efficiency, reducing the potential for human error and ensuring consistent accuracy.

Versatility Across Gear Types

The versatility of PC-DMIS Gear is a significant asset to AIS. The software supports the inspection of various gear types, including straight spur gears, helical spur gears, straight bevel gears, and spiral bevel gears. Each gear type has unique definitions and inspection requirements, and PC-DMIS Gear's dedicated algorithms and reporting graphics allow us to handle them all effectively.

Comprehensive & Certified Reports

At AIS, we prioritize transparency and thoroughness in our reporting. When utilizing PC-DMIS Gear, we provide a detailed inspection report that includes results from all measurement equipment used. Each report is accompanied by an AIS Certificate of Inspection, certifying that all inspections were performed per industry standards by trained, qualified inspectors using accredited equipment traceable to SI Units through NIST.

Commitment to Metrology Excellence

Our integration of PC-DMIS Gear reflects AIS's broader commitment to excellence in metrology. With over 20 years of experience, our team comprises dimensional experts, many of whom are ASQ-certified and proficient in Geometric Dimensioning and Tolerancing (GD&T). Our ISO/IEC 17025:2017 accreditation by ANAB encompasses over 100 inspection parameters, underscoring our dedication to maintaining the highest industry standards.

By leveraging advanced tools like PC-DMIS Gear, AIS continues to provide unparalleled inspection services across various industries, including medical, aerospace and defense, automotive, and agriculture. Our focus on adopting innovative technologies ensures that we meet and exceed our clients' evolving needs, delivering precision and reliability in every project.

If you're ready to elevate your gear inspection game, get in touch with us.