We proudly offer five types of physical calibration services, including: Temperature (-13°F to 1,220°F), Infrared Temperature to 752°F, Humidity Test Chamber range from 10% to 98%, Pressure and Vacuum from 14.7 to 10,000 psi, Torque Calibration to 600 ft. lbs. and Force Calibration in Tension and Compression to 2,000 lbs. Our services can be performed onsite at your facility or in our state-of-the-art lab.

Physical Calibration Services

Force Calibration

Pressure/Vacuum Calibration

Temperature/Humidity Calibration

Physical Calibration Specs

It’s not what’s on the front of the report, it’s what's behind it.

All we make are numbers, so they better be right. And that’s why we're measurement enthusiasts: excited when we get a new piece of equipment or a new person with different expertise in the lab. Valid measurement results are critical to manufacturing processes.

- ISO 17025 Accreditation ensures the validity of measurement results.

- Failed measurement results have consequences large and small.

- Hubble Telescope mirror distortion: A $950 million measurement error.

- Failed measurement of heart pacemaker seals: 7 Deaths, $30 million settlement.

Don’t trust the report: trust what’s behind it. Let us show you the AIS difference.

Offered AIS Services

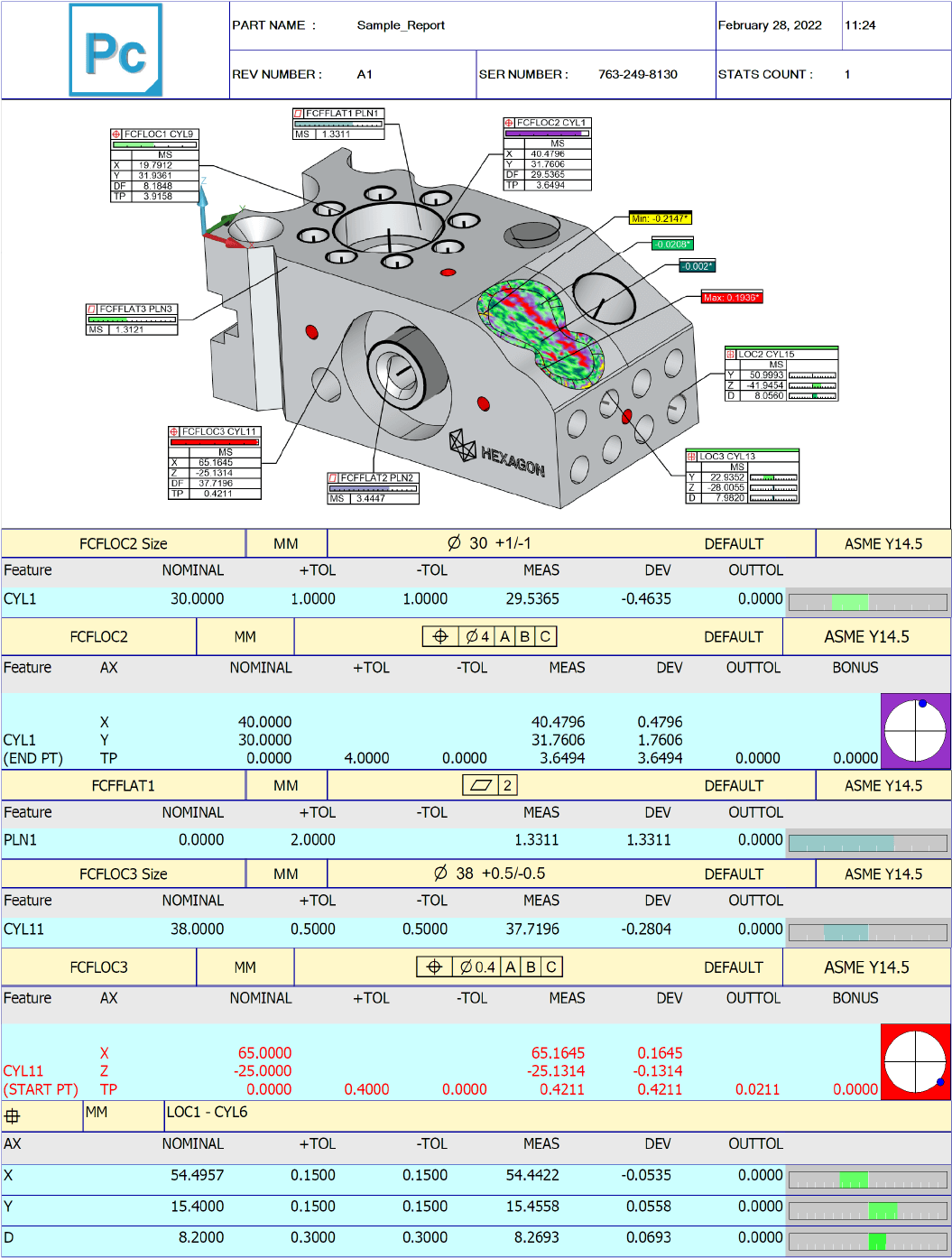

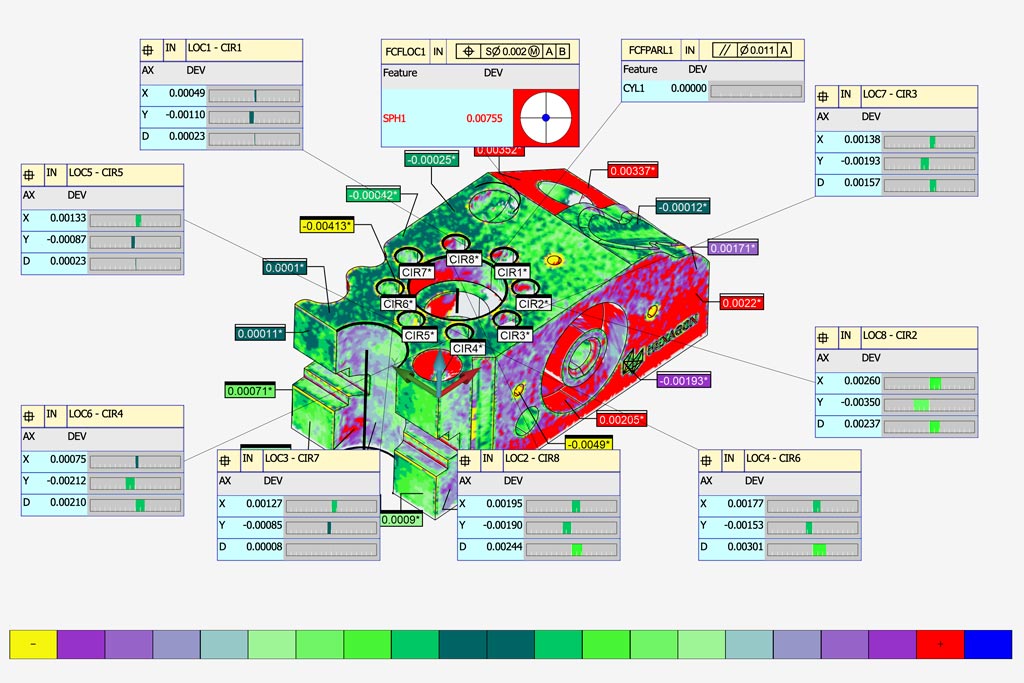

Dimensional Inspection

AIS offers dimensional inspection services for all types of manufactured parts. First article inspections, statistical analysis, and capability and gage R&R studies are our specialties. We have over 8 contact CMMs, 6 vision and multi sensor CMMs, 3 portable arm CMMs and a laser tracker with dedicated and experienced experts running them.

CT Scanning

The use of industrial CT scanning systems for metrology is one of the most significant advancements in the industry for the past 50 years: every surface, internal and external, has complete coverage with millions of points in only a few minutes. This point gathering capability is paired with state‑of‑the‑art software to intelligently manage data and report features for fast CAD‑to‑part comparisons, GD&T, and reverse engineering.

Part Digitizing & Reverse Engineering

Part digitizing is not a “one size fits all” exercise. First, an analysis of part characteristics like surface conditions, part details, or required tolerances guides us to one of our scanning technologies: portable arm laser scanning, cabinet laser scanning, structured light, interferometry, optical focus variation and confocal laser scanning.

Surface & Form Metrology

Ever shrinking part sizes and tighter tolerances require more attention than ever to a part's surface and form characteristics. Surface and form metrology requires the ability to work in the realm of nanometers. In 2018 we created a dedicated lab space just for surface and form metrology with + / - 1 degree F temperature controls and special provisions for vibration isolation. Our lab includes contact and non-contact technologies. Our results comply with ASME and ISO standards for surface and form metrology including 3D spatial parameters for surface finish analysis.

Onsite Measurement Services

Sometimes a part is simply too big to move to an offsite inspection area or even take it off the machine that is producing it. Our portable arm, laser tracker, and laser interferometer services allow you to get accredited measurement data right at your site. Dimensional inspection including GD&T, CAD to part comparisons, reverse engineering and machine geometry checks for linear, straightness, squareness, pitch and yaw can all be completed at your site with uncertainties to .000012”.